News

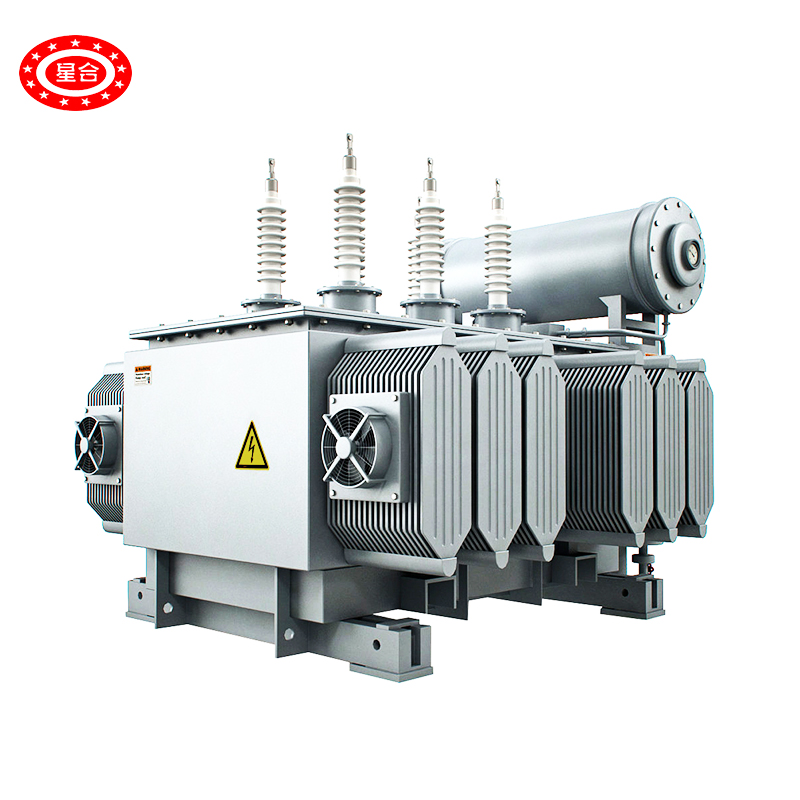

Oil-immersed transformers are a common type of electrical equipment in power systems. They are static devices that use saturated vapor or other gases as working mediums, providing excellent insulation and high-temperature resistance. Oil-immersed transformers are primarily composed of one or multiple coils, a metal core with insulation and protective sheaths, windings, and an oil tank.

In power systems, oil-immersed transformers play a crucial role in voltage regulation, capable of reducing voltage to below 10V. This means that when the current in the circuit exceeds the standard value, the equipment will automatically disconnect, ensuring the safety of the circuit and devices. Additionally, the excellent insulation and corrosion resistance of oil-immersed transformers allow them to function reliably even in harsh environments.

A transformer is a device that utilizes the principle of electromagnetic induction to alter alternating current voltage, primarily consisting of primary coils, secondary coils, and a core. By adjusting the turns ratio of the primary and secondary coils, a transformer achieves voltage increase or decrease. In power systems, transformers are crucial devices responsible for tasks such as voltage regulation, electrical isolation, and safety protection.

Oil-immersed transformers represent a type of transformer where both the core and windings are immersed in insulating oil to enhance their electrical and mechanical performance. In power systems, it play a vital role. They are capable of elevating or reducing the electrical energy generated by power plants to meet the diverse needs of users. Additionally, it provide electrical isolation and safety protection functions, effectively safeguarding the security of equipment and circuits and enhancing the stability and reliability of the power system.

Oil-immersed transformers play a critical role in maintaining the stability and efficiency of electrical equipment. Firstly, they can reduce energy loss and voltage drop, thereby improving transmission efficiency. Secondly, these transformers offer electrical isolation and overload protection. In the event of excessive loads or short-circuit faults, the transformer automatically disconnects the circuit to prevent fires and equipment damage. Furthermore, the operational costs of oil-immersed transformers are relatively low, contributing to energy savings and environmental protection.

Oil-immersed transformers are primarily categorized into two main types: single-phase transformers and three-phase transformers.

A. Single-Phase Oil-Immersed Transformer

B. Three-Phase Oil-Immersed Transformer

Oil-immersed transformers, a common type of transformer, consist of the following main parts:

Core: The core is the magnetic circuit part of the transformer, made up of laminated silicon steel sheets to transmit magnetic flux and lines of force. The core structure can be divided into a core column and a yoke. The core column houses the primary and secondary windings, and the yoke connects the core columns.

Windings: The windings are the electrical circuit part of the transformer, wound with insulated copper or aluminum wire. The primary winding receives electrical energy, and the secondary winding outputs it. The windings are supported and fixed on the core with insulation materials and are divided into low-voltage windings and high-voltage windings.

Tank: The tank is the outer shell of the transformer, designed to contain all internal components. Usually constructed from welded steel plates, the tank provides sufficient strength and sealing to ensure that the insulating oil inside the transformer does not leak.

Insulating Oil: Insulating oil is a crucial component of the transformer, serving purposes such as insulation, heat dissipation, and arc suppression. In oil-immersed transformers, insulating oil is used to immerse the core and windings, enhancing their electrical and thermal performance.

Accessories: I also include various accessories like breathers, thermometers, radiators, oil purifiers, explosion-proof devices, etc. These accessories ensure the normal operation and safety performance of the transformer.

Compared to other types of transformers, the key distinction of oil-immersed transformers lies in the fact that their interior is filled with insulating oil. This design provides excellent electrical and thermal performance but also requires regular maintenance and inspection to ensure proper operation.

Insulating oil plays a crucial role in oil-immersed transformers, manifesting in several essential aspects:

Insulation Function: Serving as the primary insulation material in oil-immersed transformers, insulating oil effectively isolates the windings and core inside the transformer, ensuring their insulation performance. Additionally, insulating oil acts as a protective barrier for the windings, preventing damage from moisture, air, and other contaminants.

Heat Dissipation Function: Transformers generate a significant amount of heat during operation. If this heat is not dissipated promptly, it can affect the transformer's performance and lifespan. Insulating oil possesses good thermal conductivity, facilitating the transfer of heat generated inside the transformer to the tank's surface. Through natural convection and radiative heat dissipation, the oil helps maintain stable temperatures within the transformer.

Arc Suppression Function: During the operation of a transformer, arc phenomena may occur, involving the discharge of electricity through the air. Arcing can damage the insulation materials inside the transformer and even lead to fires. Insulating oil exhibits excellent arc suppression properties, effectively inhibiting the generation and propagation of arcs, thereby ensuring the safe operation of the transformer.

Oil-immersed transformers, as core equipment in power systems, have found extensive applications in industrial, commercial, and power distribution settings due to their unique advantages. In comparison to other types of transformers, it exhibit distinctive characteristics and benefits.

Low Noise Level: Oil-immersed transformers are known for their low noise levels. The transformer oil, a special insulating liquid inside, absorbs and dampens internal magnetic field vibrations, effectively reducing noise. This makes oil-immersed transformers operate more quietly, minimizing noise pollution in the surrounding environment.

Enhanced Heat Dissipation: The superior heat dissipation performance of oil-immersed transformers is noteworthy. Transformer oil, serving as an excellent heat transfer medium, efficiently conducts away the heat generated during operation, ensuring the stable performance of the transformer. Compared to other transformers relying on air convection or radiators for heat dissipation, it exhibit better stability in high-temperature environments.

Lower Maintenance Costs: The enclosed design of oil-immersed transformers contributes to lower maintenance costs. The sealed oil tank design prevents the transformer oil from being easily affected by moisture and contamination, reducing the frequency of oil replacement and filtration. Simultaneously, it minimizes contact with external elements, lowering the risk of equipment damage.

Due to these advantages, it have gained widespread applications in industrial, commercial, and power distribution systems. In industries with high loads and demanding operating environments, such as steel, chemical, and paper industries, they are the preferred choice. In commercial settings like shopping centers and office buildings, where stable power supply and reduced noise pollution are essential, they are extensively utilized. In power systems, owing to their excellent heat dissipation performance and stability, oil-immersed transformers play a crucial role in high-voltage transmission and distribution.

However, despite the numerous advantages, fire prevention and explosion protection should be carefully considered during the use of oil-immersed transformers. Especially in high-temperature or electrical equipment failure scenarios, attention must be given to temperature and pressure changes in the transformer oil. Additionally, regular maintenance and inspections are key to ensuring the long-term stable operation of oil-immersed transformers.

As a core component in power systems, proper maintenance and testing of oil-immersed transformers are crucial for their reliable operation. We have provided detailed information on this topic in the article "How to Detect, Test, and Rectify Transformer Core Faults and Oil-Immersed Transformer Overhaul: What Does It Involve?".

Oil-immersed transformers, as a common type of transformers, exhibit a series of significant advantages when compared to other types. These advantages are primarily manifested in terms of stability, heat dissipation performance, safety, and cost-effectiveness.

Despite the notable advantages of oil-immersed transformers, in certain specific applications, other types of transformers might be more suitable. For instance, in environments where oil contamination needs to be avoided or where liquid insulation is impractical, dry-type transformers represent a better choice. Each type of transformer has its unique applicable scenarios and advantages, and the selection should be based on a thorough assessment of actual needs.

Contact a Xinghe representative today to learn more about our Transformer.